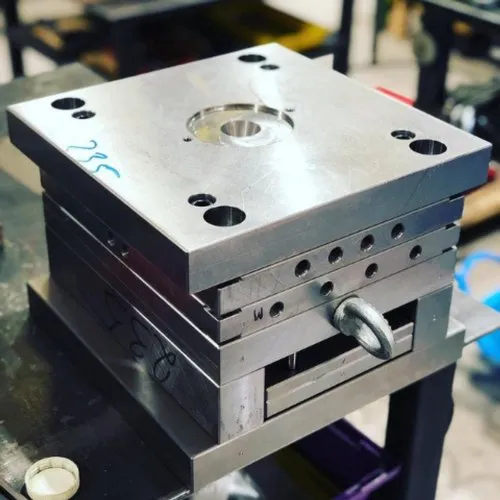

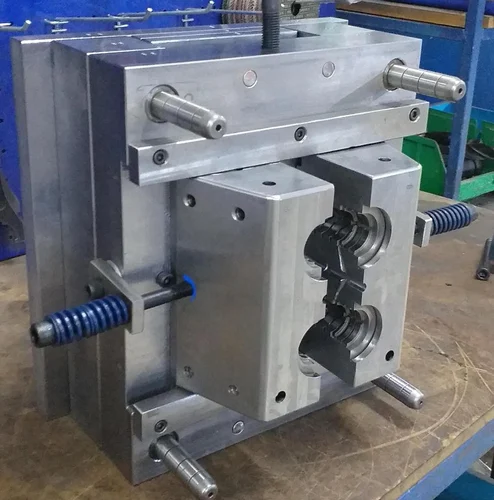

Plastic Injection Moulding

MS Auto Parts specializes in plastic injection molding to produce high-quality automotive components. Our advanced process involves injecting molten plastic into precision molds, creating durable parts like dashboards, interior trims, and exterior panels. We use versatile materials such as polypropylene and ABS, ensuring optimal performance and durability.

With efficient machinery, we meet large volume demands while maintaining tight tolerances, making our solutions cost-effective. Our design flexibility allows for intricate shapes that enhance both functionality and aesthetics. Rigorous quality control ensures every part meets industry standards, making MS Auto Parts a reliable partner in automotive manufacturing.

From 2 parts to 2 million, we meet your production needs with precision and quality.

For More Details

Enquire Now